Sold January 2004 Back to Archive

Dynamyte CNC mill - stock code 2154

Dynamyte 2400 bench-top 3-axis CNC milling machine. An ideal size for much of the work that comes through the typical model engineering workshop, this is an industrial-quality machine based on substantial iron castings for chassis, table and headstock and with a half-horsepower spindle motor (making it a good three-man lift).

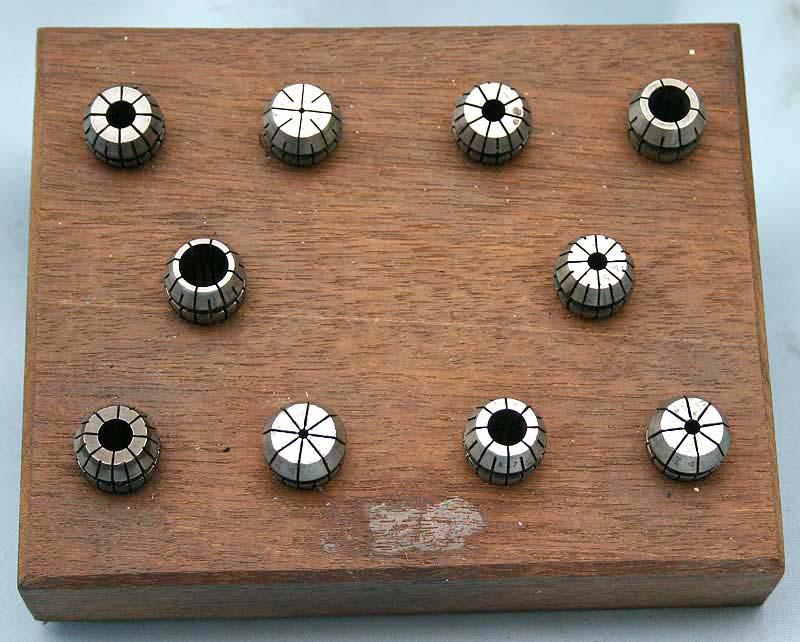

Hardened steel spindle, speed range 0-10 000 rpm. Internal taper with externally-threaded nose, allowing the use of ESX-16 collets and a wide range of screw-on tooling such as fly-cutters, slitting saw arbors etc. The quill can be manually controlled for drilling. One-shot lubrication to table.

Three axis CNC with built-in controller, featuring a powerful macro language allowing basic milling operations through to complex canned cycles, arcs, circular pockets, bolt circles etc. Programs can be repeated, mirrored, rotated and offset allowing complicated components to be programmed quickly. There is provision for storing tool offsets. The programming manual is comprehensive and includes many worked examples. The controller has a serial port, allowing programs to be created and edited on a PC if desired.

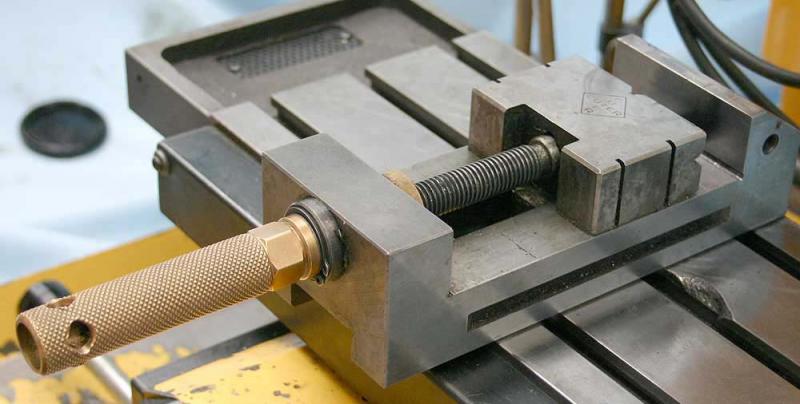

This is effectively a one-owner machine - I have known it from new and indeed it has produced bits ranging from model locomotive valve gear to oiler caps for my 12 inch scale steamroller in lunch breaks during its working life! The chip-tray paintwork is worn and there are two chips in the table - otherwise the machine is in excellent order, complete with its original programming and maintenance manuals, a set of ESX-16 collets from 1-10mm and a high quality Cuter precision machine vice.

It probably goes without saying the possibilities that CNC opens up in the workshop. I use a Bridgeport EZ-trak, which is much larger (by about a ton!) yet spends much of its time working on small components in the machine vice. Just a few of the reasons I couldn't be without it include:

Expansion links

Pitching out bolt circles on cylinder ends and covers

Milling out port faces in cylinder blocks

Making glands (I turn them off the bar then profile the bolt flange and pitch

the holes out on the mill)

Machining any kind of slots, though particularly keyways

All of which could be equally well done on this machine. (If I sound

enthusiastic, it's because I think that this is a really nice machine - if I had

more room in the workshop, I'd keep it!).

Specifications:

Max. distance spindle nose to table 9.1 inch

Spindle stroke 1.5 inch

Quill diameter 1.4 inch

Spindle speed 0-10 000rpm continously variable

X-axis travel 6.2 inch

Y-axis travel 5 inch

Z-axis travel 4 inch

Work table area 13 x 6 inch

Spindle motor 0.5hp

Overall size WxDxH 23.7 x 21.5 x 21.5 inch

Net weight 250 pounds

Resolution all axes 0.0001"

Repeatability 0.0005 inch