Sold November 2010 Back to Archive

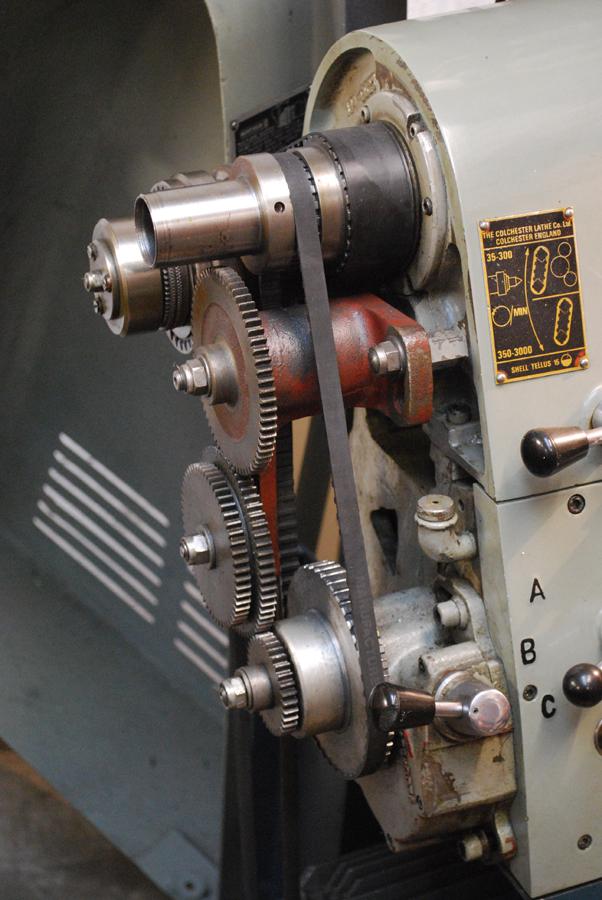

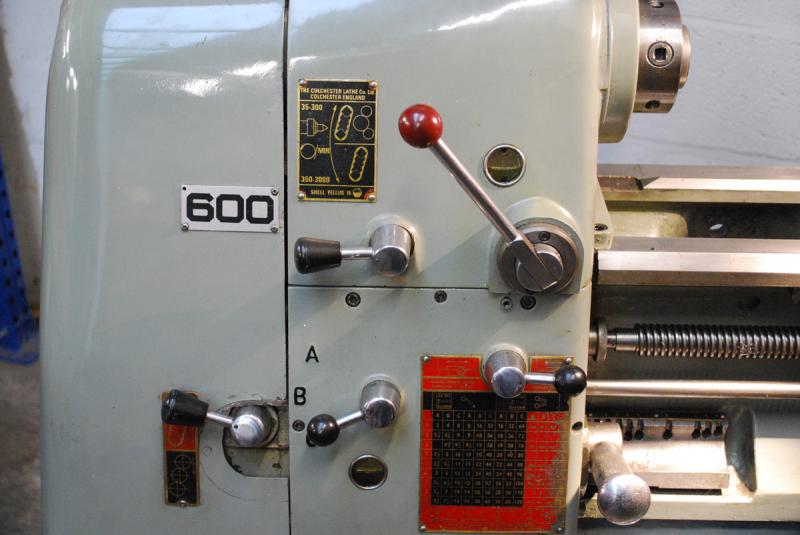

Colchester Chipmaster lathe - stock code 4298

I’m a big

fan of Colchester lathes, I started with a Bantam, acquired first one and then

another Triumph 2000, then finally changed the Bantam for a Chipmaster (the

toolroom version of the Bantam, same tooling so I could swap it all over, twice

the weight which makes for great rigidity, bigger spindle which takes the easy

to get 5C collets rather than difficult and expensive 4C and a more

comprehensive gearbox – in particular you can change between 19 and 26 tpi,

both of which in constant use, from using levers on the

Chipmaster whereas you need to delve inside the covers on the Bantam).

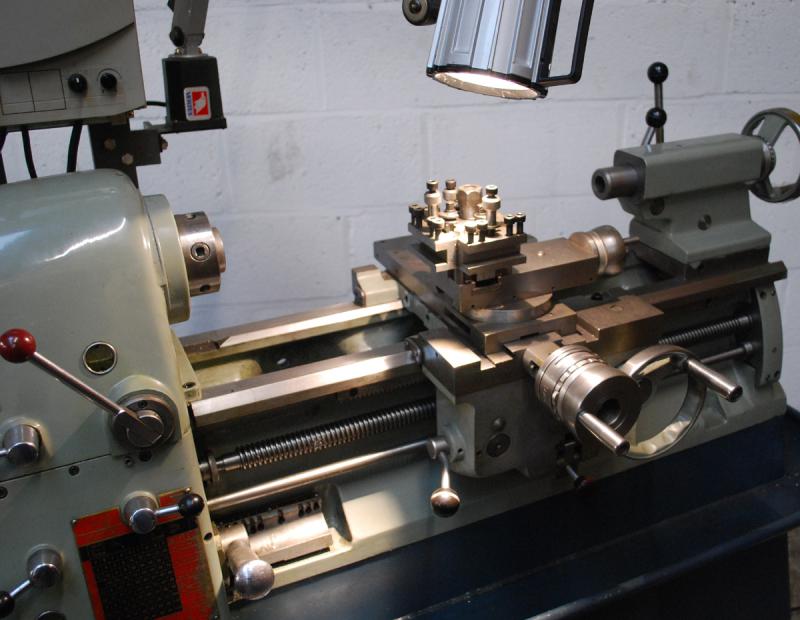

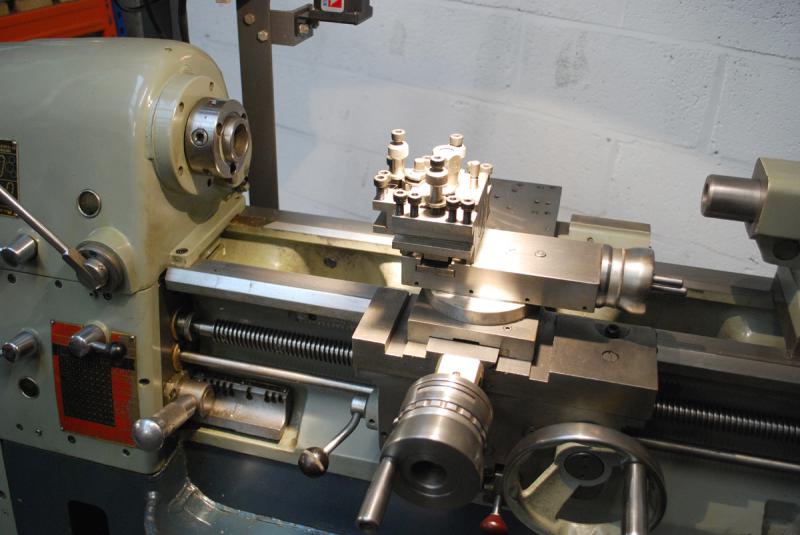

This

Chipmaster came in some months ago from a friend, I’ve agonized over keeping

it for myself - it’s the nicest one I’ve seen, super clean throughout,

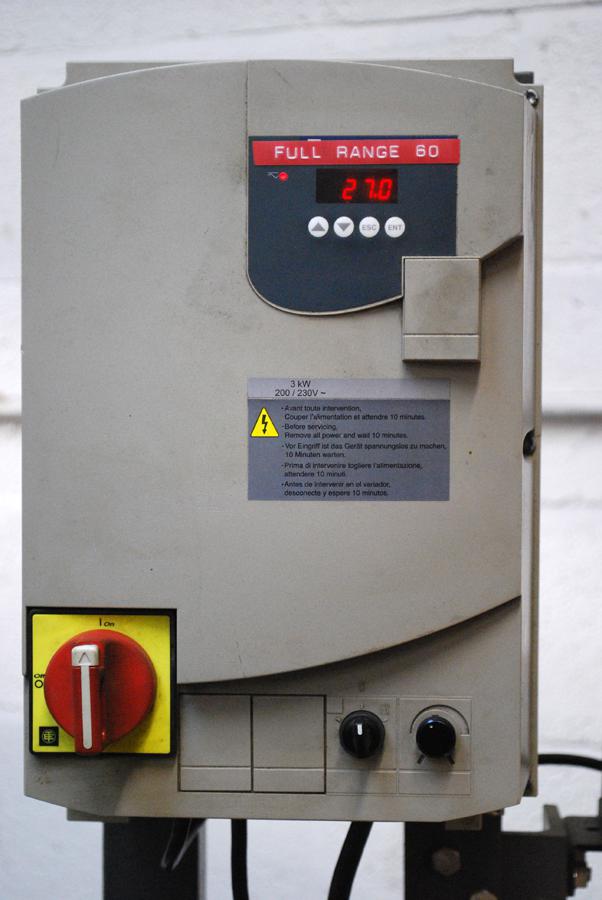

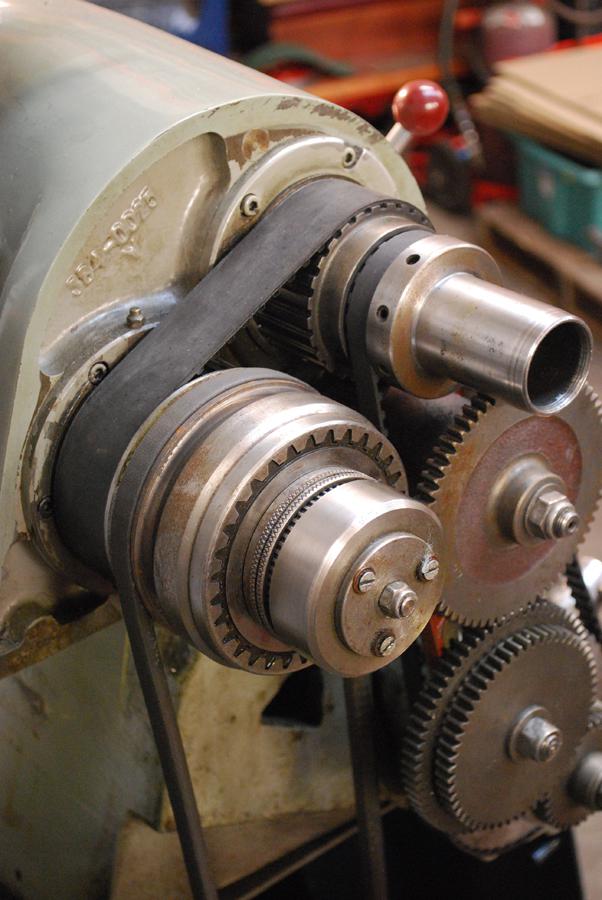

mechanically first rate. The original variator, which can be troublesome (or,

rather, noisy – our own Chipmaster is acceptable in the workshop here, but you

probably wouldn’t want to use it late at night in a domestic setting) has been

replaced by an inverter, allowing continuously variable spindle speeds at the

turn of a knob, all run from a domestic single phase 13 amp socket.

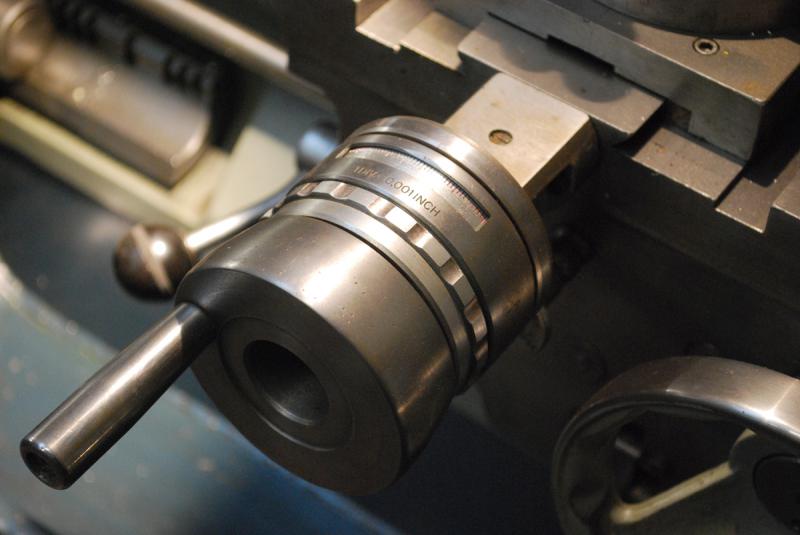

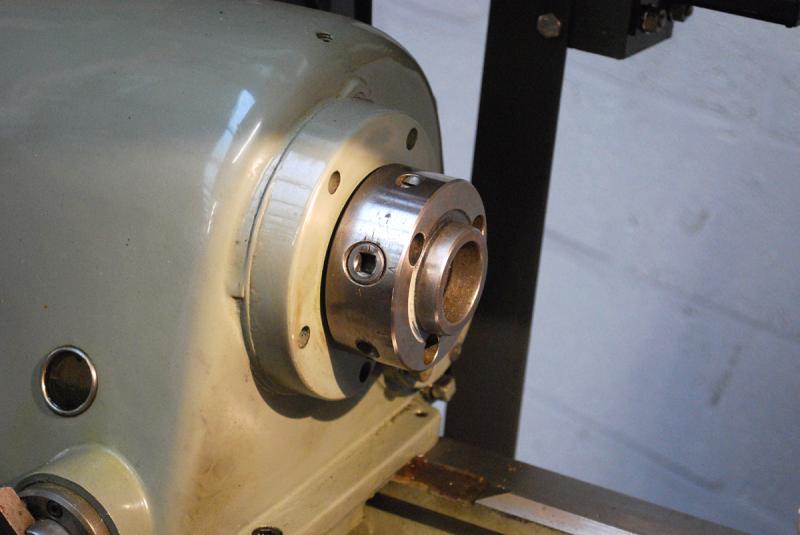

The machine

is complete with three and four jaw chucks, faceplate, catchplate, revolving

centre, quick change toolpost and halogen work light. There is a coolant pump

included although not currently fitted.