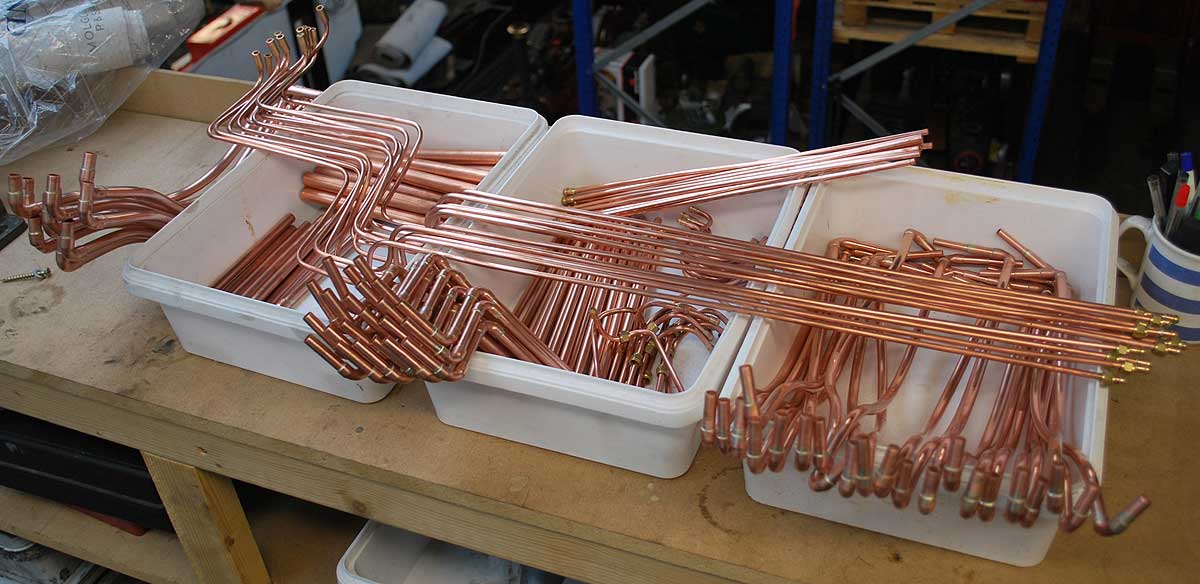

I've been plumbing up the backhead on a 7 1/4 inch gauge locomotive this week, so spending a good deal of time bending copper pipe into pretty shapes. As you all know, copper gets hard as you work it. The answer is to anneal it back to soft and carry on - it often takes two or three anneals to get to the required finished shape.

I was taught to anneal copper back when I was in short trousers - heat it up to dull red and quench, whereupon your tough, slightly springy bit of copper miraculously changes back into a pliable material with the consistency of lead.Some years later, I read that quenching was optional - a quick experiment verified (although I still do quench things simply so that I can get on a bit quicker).

This week I had a long pipe run which needed softening. Rather than mess about putting it in the hearth and getting the big torch out, I used my little portable gas blowlamp and had a go at annealing it a bit at a time. I couldn't get the whole thing hot so just played the flame on two or three inches at a time until the copper just coloured (which is a long way from dull red). Rather to my surprise it softened just as nicely - which made me wonder just how much gas I've wasted over the years getting assorted bits from central heating pipes to Triumph motorbike head gaskets red hot...