Sold August 2016 Back to Archive

15 inch gauge LNER A3 "Flying Scotsman" - stock code 5636

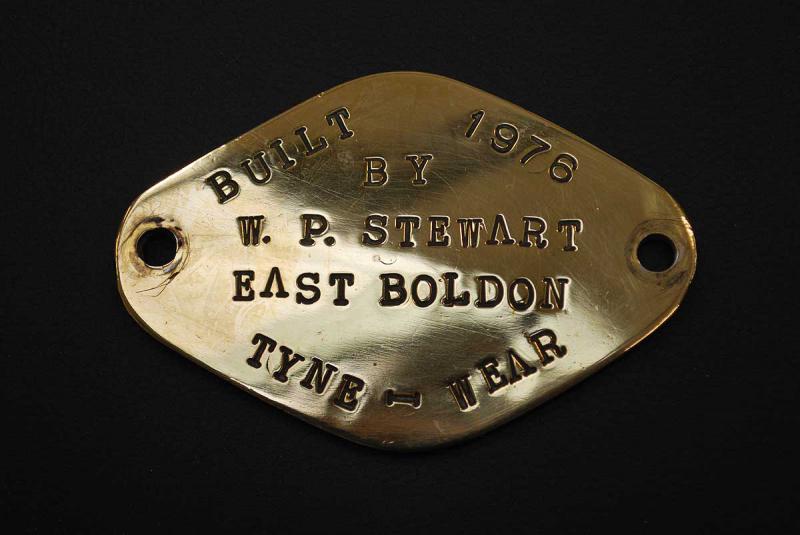

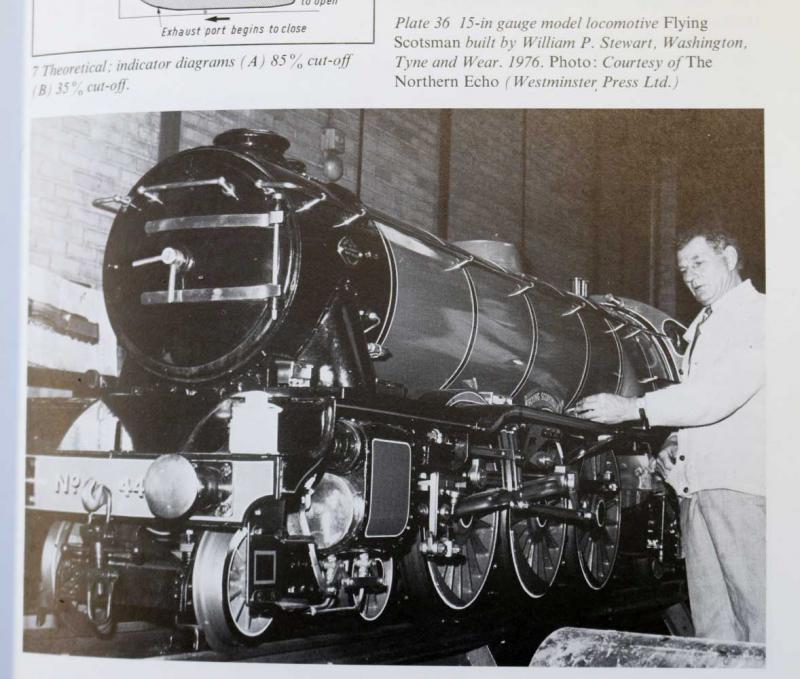

An interesting engine, built by Bill Stewart at the Washington Iron Works, Tyne & Wear and completed in 1976. The builder had experience of large engines and boilers in particular, his company having already made a new boiler for a 15 inch gauge Royal Scot and replacement boilers for two Quarry Hunslets, then running in preservation. One could imagine that, having played with the big LMS engine, he was inspired to built something similar from the LNER, given the location of his works.

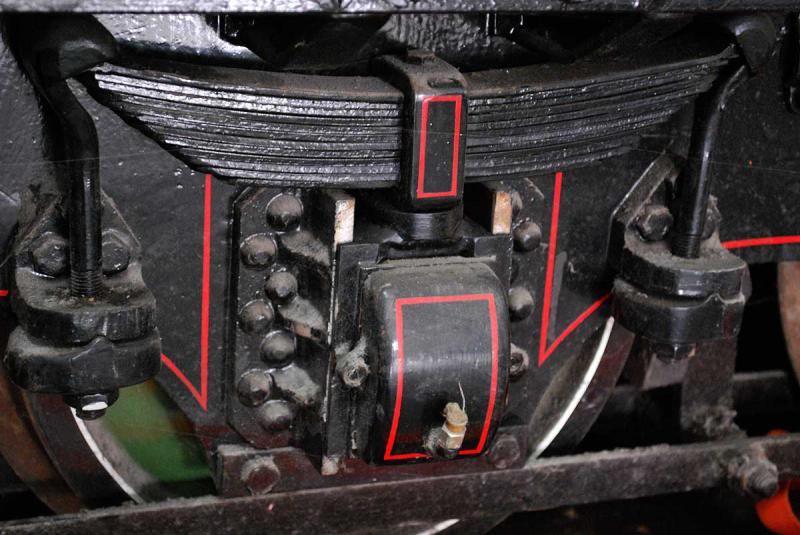

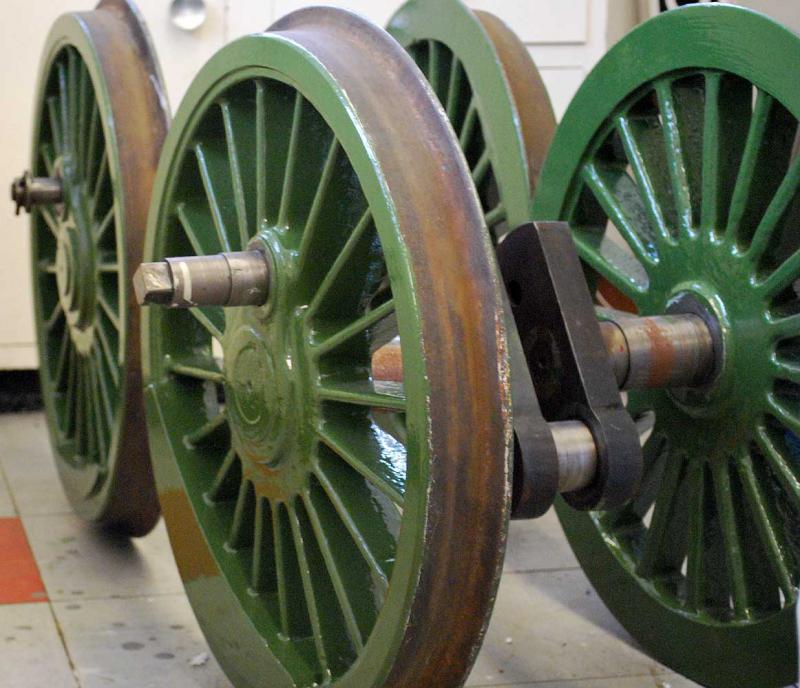

Unusual for a locomotive in this gauge, this is built to scale and highly detailed - it's a three cylinder engine with piston valves actuated by Gresley-Holcroft gear; wheels are cast in steel and run in half bronze axle boxes with felt wipers beneath; axleboxes are hung from leaf springs with prototypical V-shaped trunnion blocks pivoting on the spring hangers beneath; rear end is supported by a Cartazzi truck.

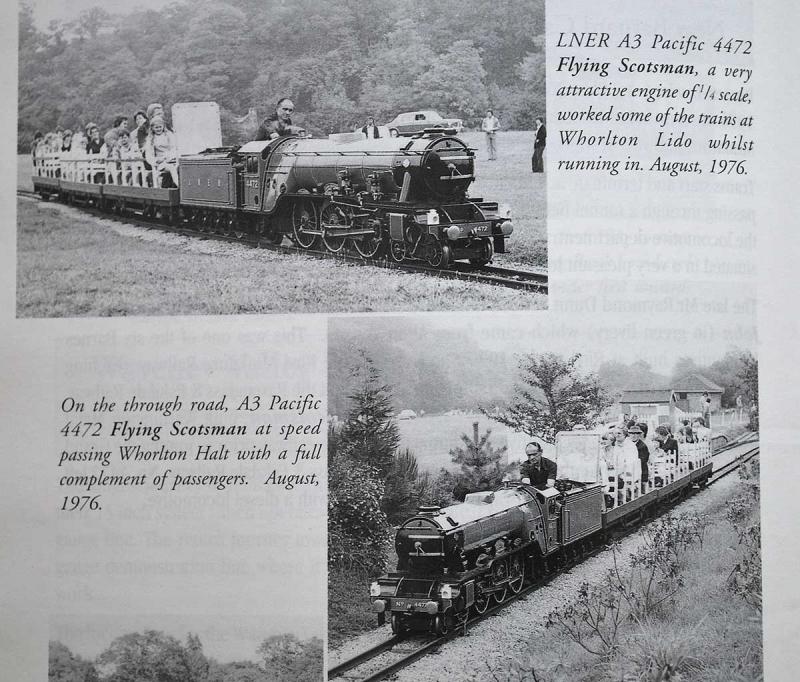

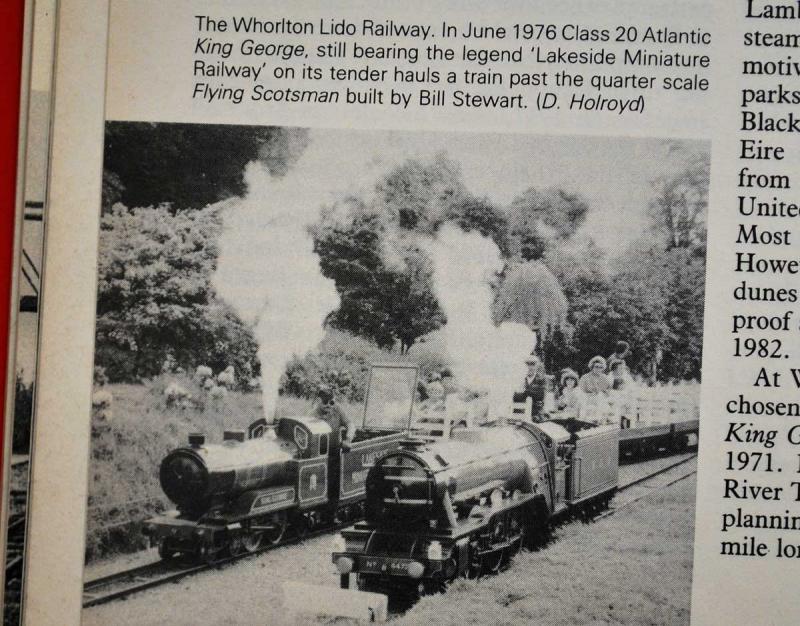

In its running career, the engine certainly got around the country - normally resident at Whorlton Lido, it visited both the Romney, Hythe & Dymchurch and Ravenglass & Eskdale Railways before moving to Bressingham Steam Museum on loan in the late 1970s where it ran on the Waverley Line there, in company with their German Krupps Pacifics.

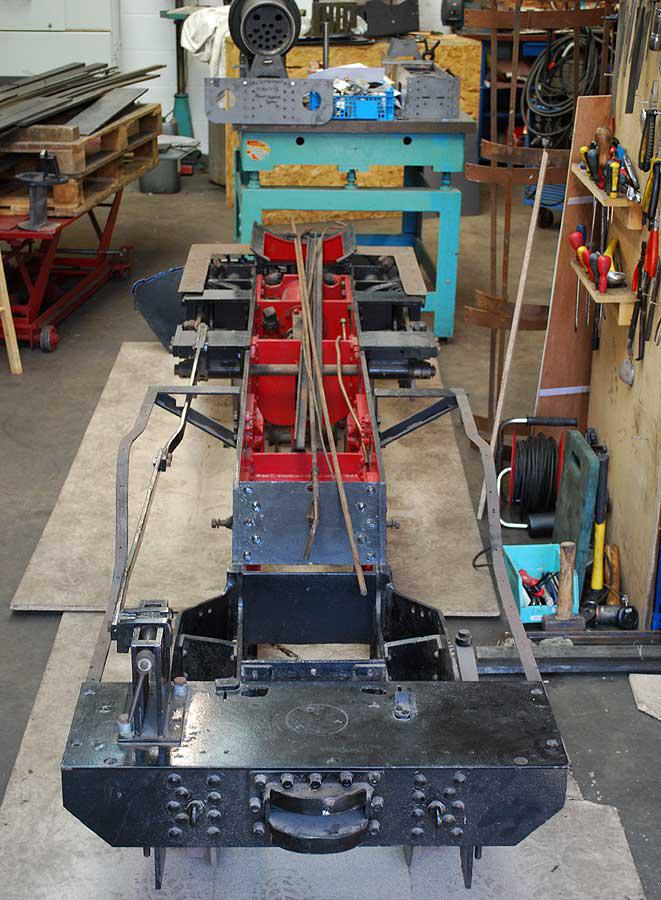

Bought by Alan Bloom for the collection in the early 1980s, the locomotive stood for some years in the shop entrance before being dismantled, for reasons largely lost in the mists of time. It was gradually reduced to a set of frames with cylinders - the wheelsets, boiler, fittings and platework being removed and stored in a variety of places around the museum. In time the tender was overhauled, repainted and lined out to a good standard and work was done on the the chassis.

"Flying Scotsman" came to us when, during a motive power crisis on the Waverley Line (the last of the serviceable German Pacifics suffered terminal boiler failure) our Exmoor-built "St Christopher" went east to Norfolk, with the A3 coming back in exchange - several of the pictures below show it on arrival in the back of the 7 1/2 tonner.

Within a couple of weeks of arrival, the engine had had a thorough inspection, our boiler inspector had looked through the superheated boiler and commented favourably on the standard of construction (it's the only one we've had in with expanded and beaded tubes) - his schedule of work called for it to be retubed, prior to a hydraulic test.

Of the remainder, I think we've got the vast majority of the bits, right down to the works plates. Main missing bits look to be the pair of mechanical lubricators (which were oversized and arguably no great loss) and a few fittings.

Whilst some work has been completed over the last couple of years, it has become increasingly obvious that new-build locomotives are taking a great deal of our time - that, combined with two major overhauls currently underway mean that the chance of the A3 seeing any serious effort any time soon are increasingly remote. That being the case, and with lack of space an ever-present problem, time has come for it to find somebody with a good-sized workshop and plenty of time to dedicate to one of the most impressive projects I've been lucky enough to own.

Length

Locomotive 12' 0"

Tender 7' 6"

From the bits we've weighed (like the boiler, which is 3/4 ton) we estimate it at about four tons in running order

| gauge | 15 inch gauge & larger |